Description

summary:

a. The temperature in traditional industrial furnaces (hot blast furnace, sintering furnace, heating furnace, secondary combustion chamber, Claus furnace, etc.) is measured by thermocouples. Assembled platinum rhodium platinum thermocouples or double platinum rhodium thermocouples are used to indirectly reflect the center temperature in the furnace by measuring the temperature near the insulation wall.

b. The working conditions in the industrial furnace are very bad, such as high temperature and high pressure. The requirements of thermocouples for the use environment and the limitations of their own structures cause inaccurate temperature measurement, delayed reaction and inaccurate reaction of thermocouples to the temperature changes in the furnace when the temperature changes frequently and the pressure fluctuates greatly and vibrates.

c. The thermocouple has been working for a long time in the high temperature zone of 1200 ℃~1300 ℃, and the ambient temperature of the thermocouple junction box is also as high as 100~120 ℃, resulting in a short service life of the thermocouple, ranging from several weeks to several months. Increased use cost and maintenance workload.

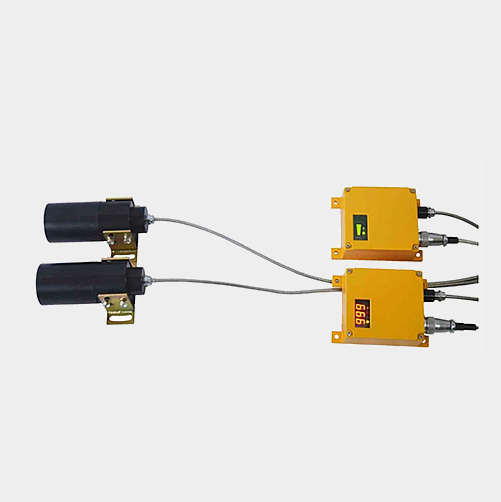

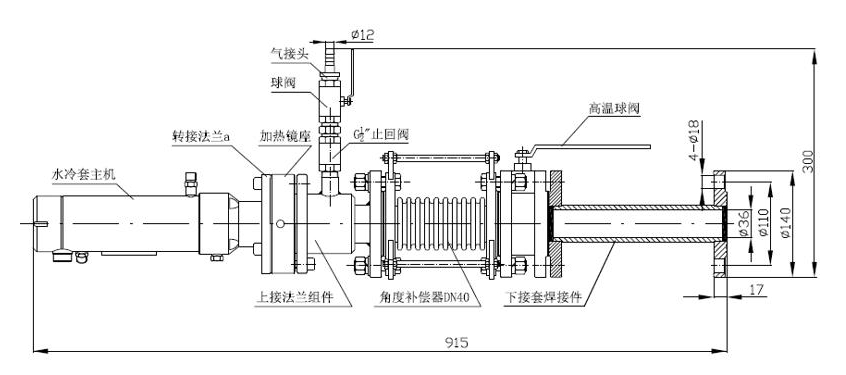

d. In order to overcome the above shortcomings, the special infrared temperature measuring device designed and produced by our company in the industrial furnace can well solve the above problems and ensure that the infrared temperature measuring system can work reliably in complex environments.

Baisteels

Baisteels